At The Scale Shop we are able to design, construct and test automatic feed and weighing systems for many industries. Over the years we have upgraded many of the Shrimp and Fish plants to enhance and accelerate systems to improve their overall capacity. These included Cooker systems to control the hourly throughput of shrimp, Shrimp bagger systems to improve accuracy of weighments, and maturing systems to effectively collect accurate data. These are just a few of the systems that have been upgraded, modified and constructed by the Scale Shop.

Control Panel Build For Caplin Dual Headed Bagging System

Control Panel Build For Caplin Dual Headed Bagging System

- Control panel build for a Caplin weighing and bagging system that accurately weighs and discharges product into packaging without the system stopping. When one hopper has reached its target weight, the second hopper starts filling. Accurate and fast.

- Customised Software

- Automatic / Manual Operation

- Variable speed conveyors for increased weighing accuracy

Retrofit Indicator and Controls for a Shrimp Bagging System

Retrofit Indicator and Controls for a Shrimp Bagging System

- Fully Customised Software

- Easily integrates into customers existing control panel

- Easily and quickly able to upgrade software for Customer

- All sensors, Variable Speed Drives and Pneumatic hardware easily Upgraded

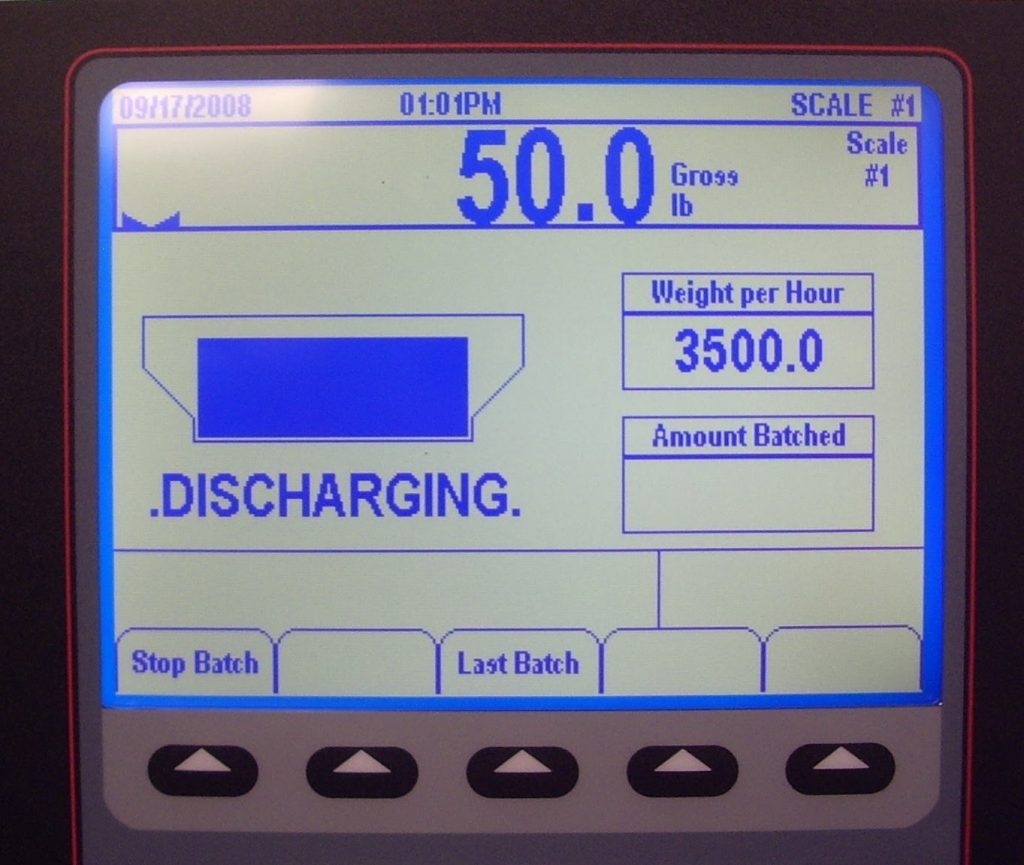

Customized Software installed on Rice Lake Weighing Systems 920i Indicator

Customized Software installed on Rice Lake Weighing Systems 920i Indicator

Over the years, we have developed and implemented many customised Software Programs utilising the Rice Lake Weighing Systems advanced 920i programmable indicator. From our own Motion Compensation Software, integrated into our WaveWeigh Marine Scale to Shrimp Sample Software, used to quickly sample and record shrimp size data. These are just a couple of examples where we have improved system controls for our Customers.